Machine

Auto Bag Fill and Seal (by weight)

Model

KSE-ABFS2000-W

Description

An automatic preformed bag filling by weight and sealing machine.

Features

- Filling by weight up to 2kg

- Operator free operation, machine runs by itself

- Picks bag from dispenser, open the unsealed portion and position it below the filling nozzle automatically

- Side clippers to taunt the filled bag, removing as much air as possible prior to sealing

- Conveyor can be added after the sealing to receive the sealed bags and transport them elsewhere

Suitable for

- Sauces

- Soups

- Pastes

- Gels

- Creams

- and more...

How it works

The Auto Bag Fill and Seal machine is an automatic filling and sealing machine for preformed bags i.e 3 sides pre-sealed and only 1 side is not.

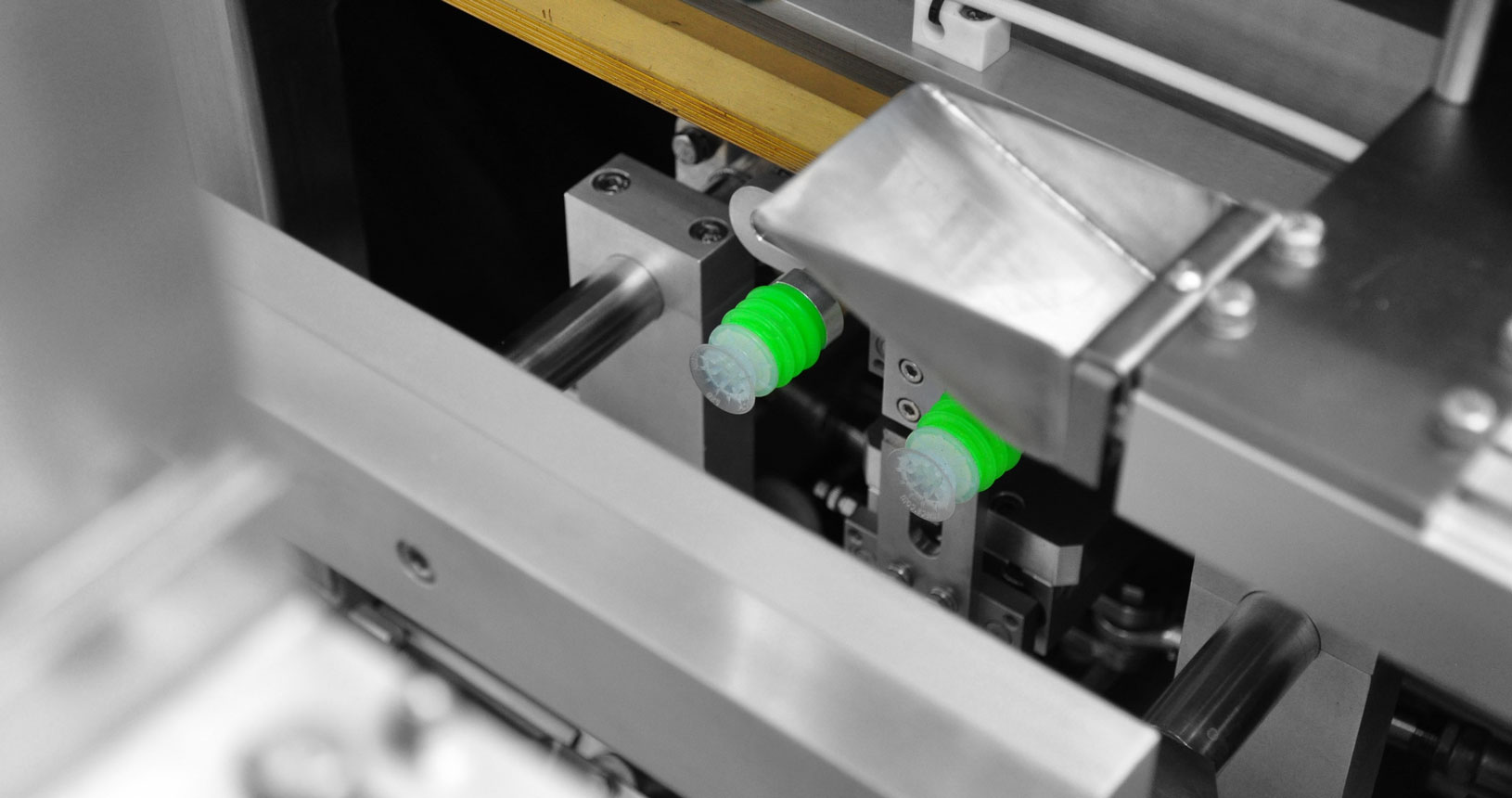

The pick and place system will retrieve 1 bag at a time from the bag dispenser. The suction cups will pull one bag out, another set will adhere to the other side to “open” the unseal side of the bag. If the bag orientation is wrong, i.e the sealed side is facing upwards, the pick and place system will reject the bag and proceed to take a new one.

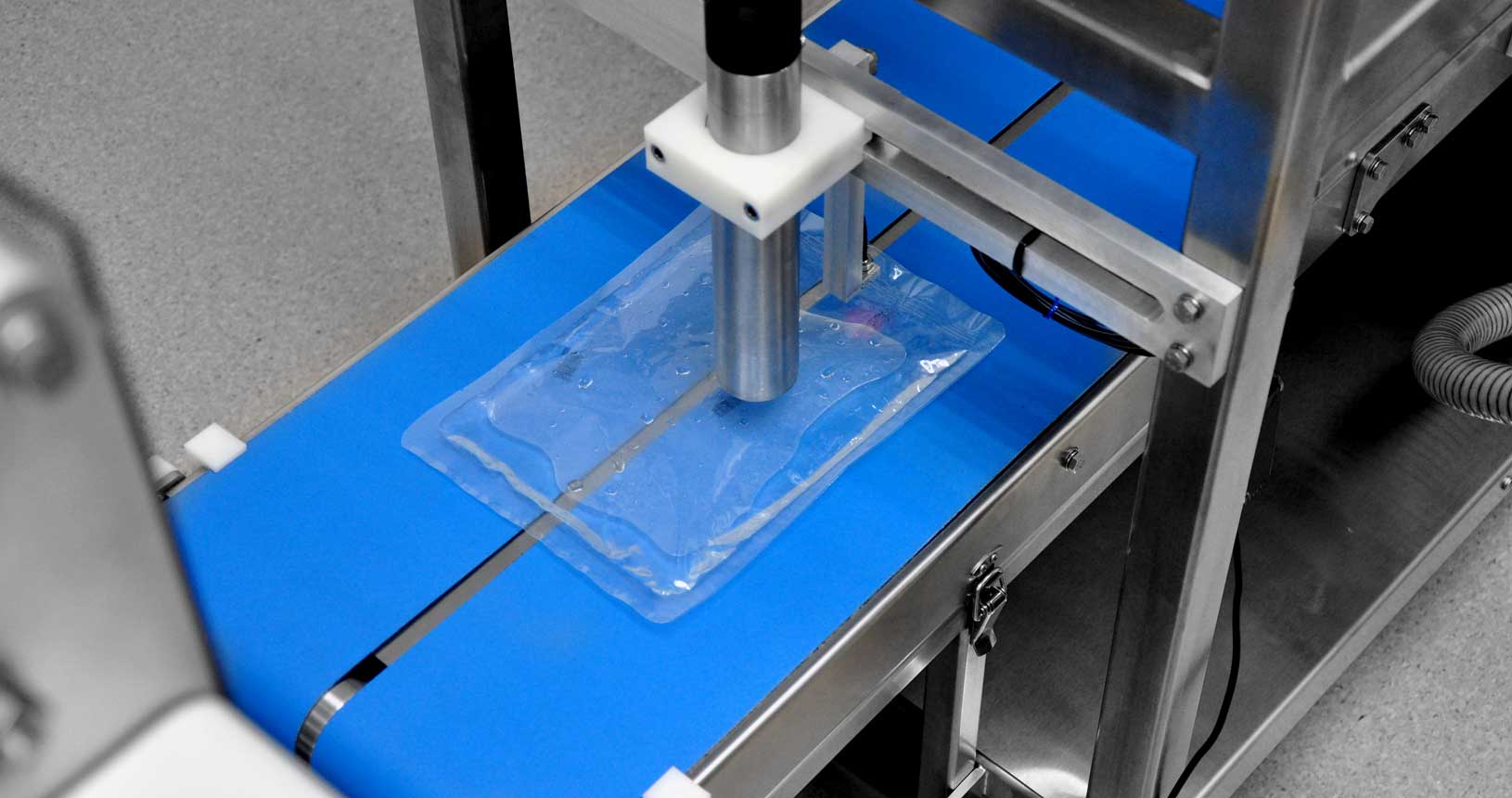

Upon successfully opening the bag, it will position it below the filling nozzle. The filling nozzle will proceed to dispense the product by the preset weight. Once the weight is achieved, it will stop and retract. The clippers on the side will taunt the filled bag to remove as much air as possible. Then it will lift the filled bag upwards to the sealing bars for sealing.

After sealing is done it will be dropped into a holding container, tray or conveyor depending on the setup the user has.

Video

Technical Specifications

| Auto Bag Fill and Seal | KSE-ABFS2000-W |

|---|---|

| Filling volume range | 500g to 2,000g |

| Bag size range |

Width - 180 to 240 mm |

| Filling temperature range | 5 to 95°C |

| Packing output | 3 to 5 bags per minute (depending on the weight) |

| Weighing |

Load cell |

| Pick and place system | Pneumatically operated Suction cups with vacuum |

| Sealing bars |

500W heaters with temperature sensor |

| Utilities | Electricity and compressed air |

| Operating voltage | Single phase, 15 amps, 230 V, 50 hz |

| Compressed air | 6 to 7 bars |

| Compressed air consumption | 50 liters/min |

| Material for machine | Stainless steel 304, 316 and Delrin |

| Weight | 246 kg |

| Dimensions (length x width x height in mm) | 1800 x 550 x 1600 |

Series

Machines from the the same series

Options

Add on equipment or machine to compliment

- Inkjet printer

- Hopper with mixer or impeller

- Vertical lifter to connect 2 conveyors of different height

eBrochure

eBrochure available via the download button.

Enquiry now

Do you know you can view or test our machines with your products?

Contact us today to find out more!

- enquiry@kse.com.sg

- +65 6747 0269