Machine

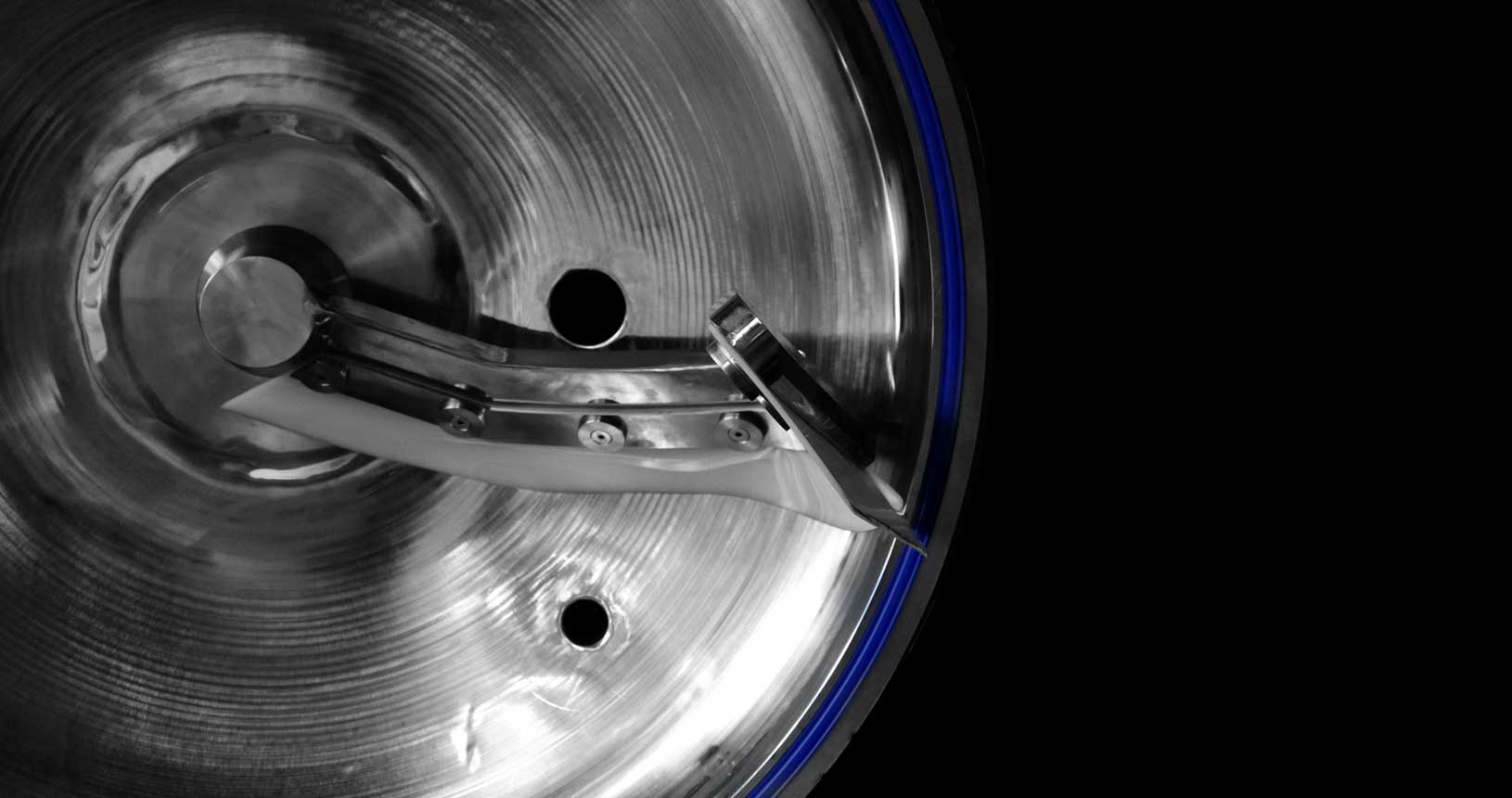

Multi Function Steam Cooker 200

Model

KSE-MFSC200

Description

The 200 litres Multi Function Steam Cooker is a processed cheese cooker that can do sauces, confectionary spreads, soups and more as well.

Features

- 10 minutes to boil 100 litres of water

- Direct steam injection and jacketed steam heating

- Process or cook under vacuum, enclosed environment

- Storable recipes with different cooking parameters

- Full range of supporting accessories available

Suitable for

- Processed cheeses - mozzarella, cheddar, spreadable cream cheese and more.

- Asian and western sauces - sambal, oyster, ketchup, laksa, chilli and more

- Confectionary spreads - flavoured jams, custard, cream, kaya, cheese cake, chocolate, strawberry, hazelnut spreads and more

- Asian or western soups - tonkotsu ramen broth, bah kut teh, lobster bisque, cream of mushroom, spinach and more

How it works

The 200 litres Multi Function Steam Cooker is a multi function and usage processed cheese cooker that can do sauces, confectionary spreads, soups and more as well.

Able to process, cook, heat, cool, mix, cut, blend and vacuum. The various parameters can be controlled via the touch screen.

Users can preload the ingredients into wagons, and load them into the MFSC using a lifting loader. Next user can select a saved recipe program, load it and start the cooking process. Once the cooking is done, the user can discharge the finished product into a wagon or transfer hopper.

The accordion below will explain further the various capabilities of the MFSC.

Video

Core capabilities

Technical Specifications

| Multi Function Steam Cooker 200 | KSE-MFSC200 |

|---|---|

| Capacity | 200 litres |

| Pressure range | Vacuum -0.4 bars to atmospheric |

| Temperature | Up to 115°C, depending on the medium |

| Heating | Direct steam injection and jacketed steam heating |

| Cooling | Ambient water temperature by default User can opt for chill water as an add-on |

| Water dosing | Flow meter |

| Scraper speed | 12 to 18 rpm |

| Knives type | Blunt, sharp, serrated |

| Knives speed | 300 to 1,500 rpm |

| Bowl, bowl cover operation | Mechanical |

| Utilities |

Electrical |

| Operating voltage | 3 phase, 82 amps, 415 V, 50 hz |

| Power consumption | 47 kW/hr |

| Water | Potable water |

| Compressed air | 6 bars, constant |

| Steam | 300 - 350 kg/hr, 4-6 bars |

| Material for machine | Stainless steel 304 and 316 |

| Weight | 1790 kg |

|

Dimensions (length x width x height in mm) |

2430 x 1300 x 1800 |

Others

Machines or equipments that compliments the Multi Function Steam Cooker series

- Wagon and Loader

- Hopper with transfer pump

- Form Fill Seal

- Cheese Grinder

- Cheese Cutter

eBrochure

eBrochure available via the download button.

Enquiry now

Do you know you can view or test our machines with your products?

Contact us today to find out more!