Machine

Cheese Cutter 500

Model

KSE-CC500

Description

A cutting machine to divide a single processed cheese block into smaller cubes or blocks.

Features

- Blades or wires

- Customisable cutting length and width

- Easy to replace blades or wires

Suitable for

- Processed cheese blocks

- Butter blocks

- Solid fat blocks

How it works

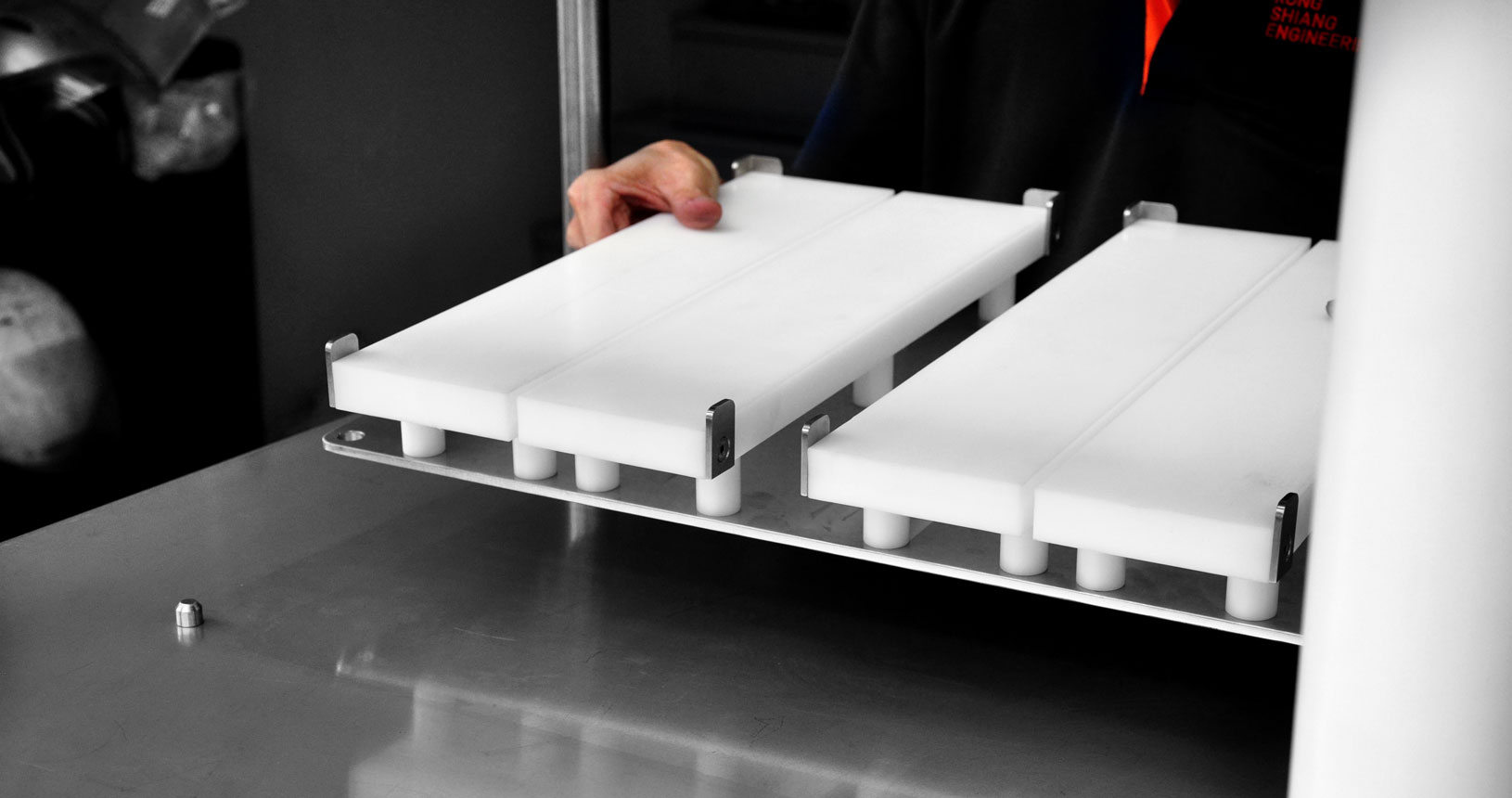

Operator prior to loading the processed cheese block on the cutting base has to ensure the safety blocks are in place. Once the block is in place, the user can then remove the safety blocks. Simply press both start buttons at the same time to activate the cutting process. The cutting grid will slowly come down to ensure a smooth and even cut.

The blades or wires will cut through the processed cheese blocks and the base has gaps to cater for it; this ensures a very clean cut.

Once cut, the cutting grid will slowly rise back up, the user can add the safety blocks back again to prevent the cutting grid from accidentally activating. The cut processed cheese blocks can then be removed safely.

Video

Technical Specifications

| Cheese Cutter 500 | KSE-CC500 |

|---|---|

| Cutting size | Customisable |

| Recommended core temperature of the block | 10°C and above |

| Holding capacity | 1 block |

| Utility | Compressed air supply, 6 bars constant |

| Material for cutting base and block | Delrin |

| Material for machine | Stainless steel 304 and 316 |

| Weight | 130 kg |

| Dimensions (length x width x height in mm) | 880 x 700 x 1230 |

Series

Machines from the the same series

eBrochure

eBrochure available via the download button.

Enquiry now

Do you know you can view or test our machines with your products?

Contact us today to find out more!

- enquiry@kse.com.sg

- +65 6747 0269